Your current location:Home > Technical Support > Tempering furnace > Forced convection circulating heating furnace body of high temperature fan

Your current location:Home > Technical Support > Tempering furnace > Forced convection circulating heating furnace body of high temperature fan

Replace the old radiant heater as a whole

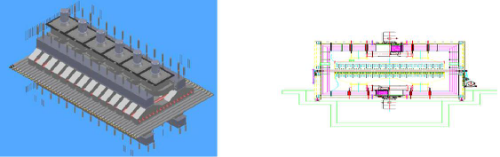

Forced convection circulation heating furnace body for upper and lower high temperature fan

Part 1: business content

1. name of goods: upper and lower high temperature fan forced convection heating furnace body, the corresponding electrical software and hardware changes.

2. scope of supply:

Heating furnace (upper and lower high temperature fan forced convection, circulating heating), corresponding electrical control system (hardware and software).

Part 2: Equipment Introduction

The structure of the heating section is of a double-layer box type covered with thermo-insulating material. Inside the section there is a conveyor system with high temperature resistant ceramic rollers, which are imported from well-known manufacturers.

There are 5 high temperature cycle blowers on the top of furnace and 2 blower on the bottom furnace. The heating elements are arranged longitudinally in the furnace in order to focus heat efficiently and to be able to create so called heating profile for convection air. Upper and lower part of the furnace work in synchronization. The heating elements are spiral type resistance wound on ceramic pipes and parts. They are easy to replace.

When the glass(es) enter into the furnace, the front door of the heating section opens, the rolls of the loading table and heating section transfer the glass with the same speed. When the glass is in the furnace, the front door closes and the glass oscillation is controlled automatically so that the glass will be heated evenly.

The furnace upper section can be lifted up by remote control for maintenance.

Technical Data

2.1 Technical Specifications

Productivity / Process cycle time:

20 - 25 Loads per hour for 5 mm clear float glass

17 - 20 Loads per hour for 5 mm LOW-E glass

Heating speed

28~36 s/mm(clear float glass)

36~42 s/mm(low-E glass)

Material of oven blower

AISI 310S

Power of oven blower

2.2-7.5kW

Material of convection structure

AISI 310S

Base of blowers

vibration absorbed

Control for blowers

by inverter

Number of convection blower

The lower part is in accordance with the specifications of the furnace

Power consumption:3.5 Kwh per square meter

Suitable glass types:

Clear float glass

Coated glasses

soft LOW-E glass,e>=0.01

Patterned glass

Tinted glass

2.2. Supply Scope

- Forced Convection Heating Section (Furnace)

- Associated Electrical and Control Equipment

- Control Terminal

3. Acceptance Test

1. acceptance inspection products: three varieties of specifications within the contract indicators.

2. acceptance test indicators: contract quality and rate of finished products and power consumption.

3., acceptance method is: After Party B think the equipment is normal, will each kind of specifications debugging end, both sides acceptance begins, continuous life

Produce 4--8 hours.

4. Testing glass size:

4MM

500×800mm

20片

5MM

800×1200mm

20片

6MM

865×1950mm

10片

8-10MM 865×1950mm

10片

15MM

865×1950mm

6 片

19MM

865×1950mm

2 片